| Areas | |

|---|---|

| Serie de libros (96) |

1381

|

| Nachhaltigkeit |

3

|

| Gesundheitswesen |

1

|

| Letra |

2370

|

| Ciencias Naturales |

5408

|

| Ciencias Ingeniería |

1795

|

| Ingeniería | 292 |

| Ingeniería mecánica y de proceso | 862 |

| Ingeniería eléctrica | 688 |

| Mineria y metalurgía | 30 |

| Arquitectura e ingeniería civil | 75 |

| General |

98

|

|

Leitlinien Unfallchirurgie

5. Auflage bestellen |

|

Erweiterte Suche

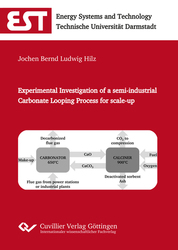

Experimental Investigation of a semi-industrial Carbonate Looping Process for scale-up (Tienda española)

Jochen Bernd Ludwig Hilz (Autor)Previo

Indice, PDF (34 KB)

Lectura de prueba, PDF (73 KB)

An efficient post-combustion capture technology is the carbonate looping (CaL) process reducing the amount of CO2 released by fossil fuelled power and industrial plants (CCS/U). Limestone based sorbents are circulated between two interconnected circulating fluidized bed (CFB) reactors. In a first reactor, the carbonator, the main part of CO2 contained in the flue gas of an upstream emission source is absorbed by CaO. The CO2 is released and the sorbent regenerated under oxy-firing conditions in a second reactor, the calciner. The present work discusses the results obtained from experimental investigation of the Carbonate Looping process in semi-industrial 1 MWth scale. Long-term pilot tests were conducted to improve the process and gain reliable experimental data to scale up the CaL process to industrial size. The type of fuel, sorbent, flue gas composition, reactor design, and operating conditions were varied to assess the operability and the long-term effects on the process performance. During periods of up to 60 h, parameters were not changed to achieve steady-state conditions. The stability of the CaL process in semi-industrial size was proven by steady-state CO2 absorption for more than 1,500 h with interconnected circulating fluidized bed reactors with absorption rates in the carbonator higher than 90% and overall capture rates higher than 95 %. The experimental data obtained in this work provide the basis to take the CaL process to the next stage of development, a demonstration pilot with a thermal size of 20 MWth. A conceptual plant setup for this demonstration unit was derived from the operational experience in the 1 MWth pilot plant. Based on evaluation of pilot testing and with the help of a validated process model, the design parameters were defined and verified. The heat and mass balancing for various operating cases was carried out to define the boundary conditions for the engineering of the demonstration pilot. Furthermore, the assessment of the demonstration pilot showed the expected performance.

| ISBN-13 (Impresion) | 9783736970458 |

| ISBN-13 (E-Book) | 9783736960459 |

| Formato | A5 |

| Idioma | Inglés |

| Numero de paginas | 170 |

| Laminacion de la cubierta | mate |

| Edicion | 1. |

| Lugar de publicacion | Göttingen |

| Fecha de publicacion | 08.07.2019 |

| Clasificacion simple | Tesis doctoral |

| Area |

Ingeniería mecánica y de proceso

|

| Palabras claves | Attrition, CaL (Carbonate/CalciumLooping), Calcination, Calciner, Calcium Carbonate, Calcium Oxide, Carbonation, Carbonator, Carbondioxide, CCS (Carbon Capture and Storage), CCU (Carbon Capture and Utilization), Cement, Circulating Fluidized Bed, CO2 Capture, Combustion, Demonstration Pilot, Dual Fluidized Bed, Experimental Investigation, Flue Gas Cleaning, Hydrodynamcis, Industrial Plants, Limestone, Oxyfuel Regenerator, Oxyfuel Technology, Pilot Plant, Post-Combustion, Power Plants, Process Engineering, Retrofit, Scale-up, Solid Fuel, Solid Looping, Semi-Industrial, Kalzinierung, Karbonisierung, CO2, Zement, Zirkulierende Wirbelschicht, CO2 Abscheidung, Verbrennung, Demonstationsanlage, Experimentelle Untersuchung, Rauchgasreinigung, Industrieanlagen, Kalkstein, Versuchsanlage, Kraftwerkstechnik, Verfahrenstechnik, Nachrüstbarkeit, Skalierung, Festbrennstoff, Semi-Industriell |