| Departments | |

|---|---|

| Book Series (96) |

1381

|

| Nachhaltigkeit |

3

|

| Gesundheitswesen |

1

|

| Humanities |

2370

|

| Natural Sciences |

5408

|

| Engineering |

1795

|

| Engineering | 292 |

| Mechanical and process engineering | 862 |

| Electrical engineering | 688 |

| Mining and metallurgy | 30 |

| Architecture and civil engineering | 75 |

| Common |

98

|

|

Leitlinien Unfallchirurgie

5. Auflage bestellen |

|

Advanced Search

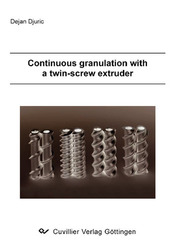

Continuous Granulation with a Twin-Screw Extruder (English shop)

Dejan Djuric (Author)Preview

Table of Contents, Datei (26 KB)

Extract, Datei (170 KB)

Continuous granulation with a twin-screw extruder

Dr. Dejan Djuric

The feasibility of a twin-screw extruder for a continuous wet granulation process was investigated. On the one hand the impact of different screw configurations and process parameters on granule and tablet properties was evaluated. On the other hand mixing properties of several screw configurations were tested with respect to a continuous process including mixing and granulation in one process step. Furthermore a comparison of differently sized twin-screw extruders was performed to evaluate differences and similarities between both machines.

Screw configuration had a major impact on granulation behaviour. The tested screw configurations led to similar granule characteristics irrespective whether lactose or mannitol, as water-soluble substances, or dicalcium phosphate, as a water-insoluble substance, was agglomerated. Conveying elements generally produced easy-flowing granules with the highest amounts of fines, porosity values and thus highest granule friability. Combing mixer elements also produced easy-flowing granules with less amounts of fines and lower porosities. Kneading blocks achieved free-flowing granules with negligible amounts of fines and the lowest porosities. In general increasing granule porosity led to higher tensile strengths of tablets. Finally the element combination of kneading block and combing mixer element proved to be the screw configuration of choice for all substances. Agglomeration behaviour of the tested screw configurations was comparable for 2kg/h and 6kg/h powder feed rate, respectively, providing the possibility of a simple increase in material output regarding a possible scale-up.

Process parameters also had an influence on granule characteristics. Amounts of fines and granule friability decreased with higher water content as well as with increasing screw speeds. More abrasive granules resulted with increasing powder feed rate.

Distributive mixing was tested concerning water and API content of granule samples. All tested screw elements, except the 15mm pitch conveying element, showed good distributive properties. Dispersive mixing was only achieved by the use of kneading blocks.

Comparison of two differently sized twin-screw extruders showed that the extruder type had a high influence on properties of lactose and dicalcium phosphate granules. An increasing total input rate amplified agglomeration of water-soluble and water-insoluble substances resulting in lower amounts of fines and coarser granules. The larger extruder produced coarser granules with lower amounts of fines. The smaller sized extruder led to granules with higher amounts of fines and less oversized agglomerates due to less mechanical input. However, both extruders produced easy- or free-flowing granules. For both substances the resulting tablets did not show an influence of extruder type or process variable.

| ISBN-13 (Printausgabe) | 3867276439 |

| ISBN-13 (Hard Copy) | 9783867276436 |

| ISBN-13 (eBook) | 9783736926431 |

| Language | English |

| Page Number | 220 |

| Edition | 1 Aufl. |

| Volume | 0 |

| Publication Place | Göttingen |

| Place of Dissertation | Düsseldorf |

| Publication Date | 2008-07-18 |

| General Categorization | Dissertation |

| Departments |

Engineering

|

| Keywords | granulation, twin-screw extruder, continuous processing, tabletting |